Common Problem Q&A

Q7 How to adjust measurement?

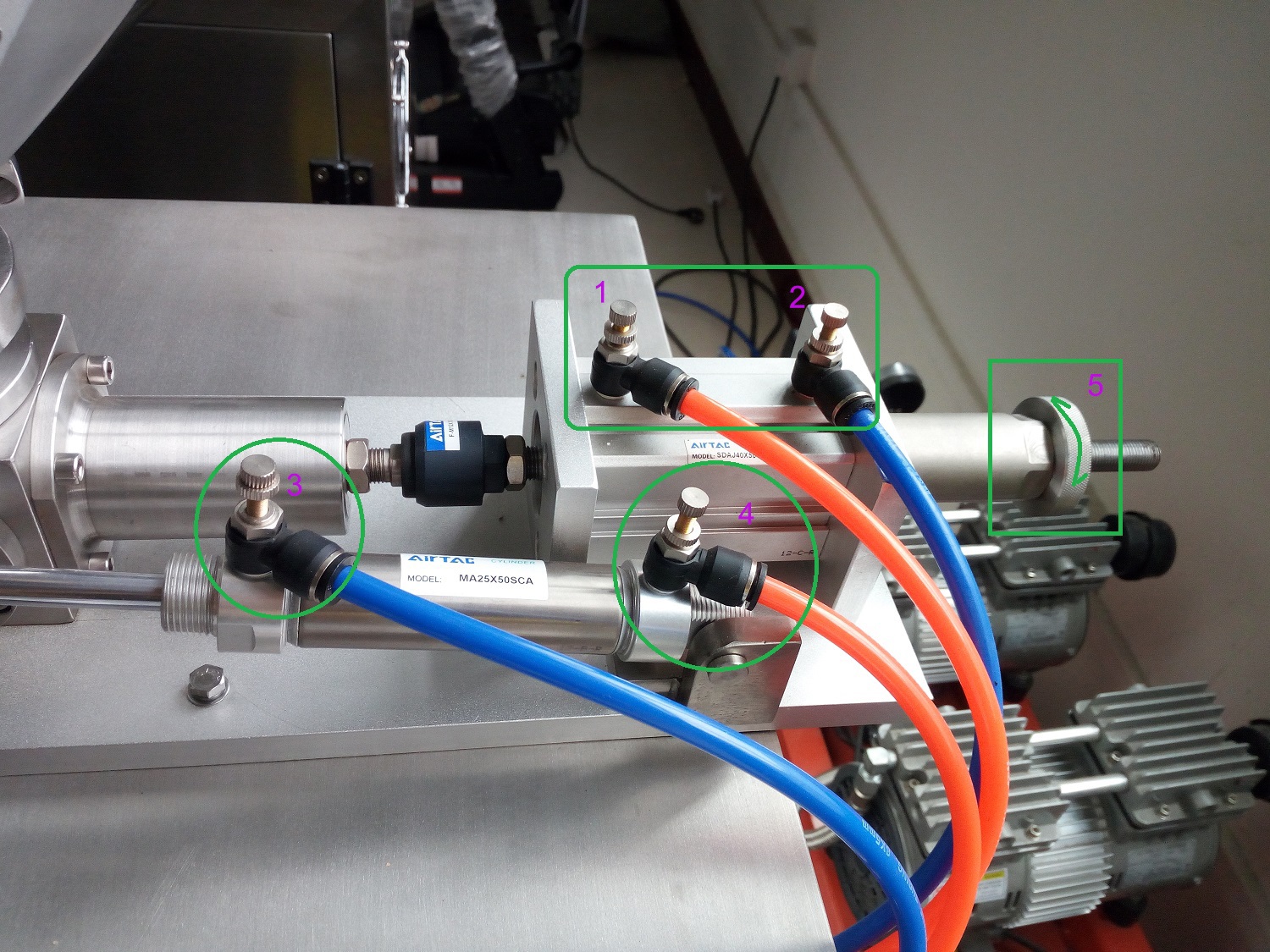

A7:Adjust the air pressure of small cylinder by screw 3/4 to the biggest and slow the air pressure of cylinder by screw 1/2. This step is adjust the accuracy of the measure. By rotary the screw 5 to adjust the distance of the pump work to control the weight we need.(See attached video” how to change the weight)

Q: How to Clean the pump filler?

A:when the production is finished and clean the products, take the filling pipe from bag former out and then put the water into the hopper and adjust the biggest weight to run the machine about 15-30minutes. If your product is very serious, you can remove the pump to wash it. Please carefully do that when you take off the pump and remember the steps so that you can install it as the former steps.

Q1 “Trace error”

A1:Press “ESC”, adjust the distance between film mark and photocell spot by pressing “ (on main screen)“or pressing yellow button(Inching Pull),light off when spot meet mark area, vise verse, then press” start”.

(on main screen)“or pressing yellow button(Inching Pull),light off when spot meet mark area, vise verse, then press” start”.

Q2 How to reset output number?

A2:press “ESC” for 3 seconds(On the Running Monitor Screen)

Q3 How to change the cutting type(from one by one to multi pcs by multi pcs)?

Reset the “Count Cut” number ( Parameter Set Screen---Basis Parameter---Count Cut)

Q4 How to set the quantity number which we want to pack?

Reset” ProutSet” number( Parameter Set Screen---Basis Parameter---Proutset)

Q5 How to set temperature if we use different packing material?

Adjust on the temperature panel as picture:

Q6 How to fix if the bag out of the fulling wheel?

See attached video” bag out problem).

Q8 How to change roll film?

A8: machine will stop if there is no film, See attached video” how to fix the film roll)

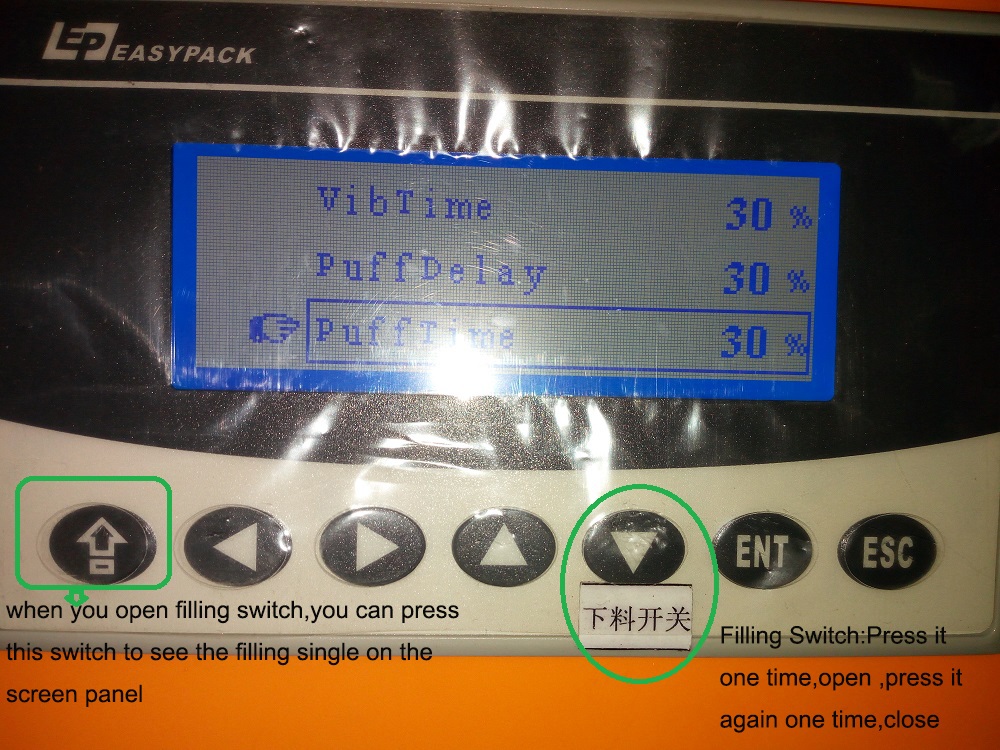

Q9: How to open filling Switch For Paste or liquid?

A9: Filling Switch: Press it one time, open ,press it again one time, close

You can press " up“ to filling switch state "open or close" See the picture as follow

Installation vedio: https://www.dropbox.com/sh/8kazopu1y9osqgt/AACCH0geYqXLyx38F8k3yN8sa?dl=0